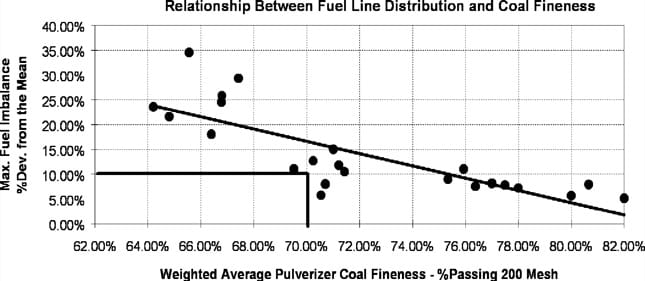

Higher fineness levels always promote more even distribution of fuel between a pulverizer’s separate burner lines. Better distribution promotes better combustion, inherently lower NOx emissions and lower flyash L.O.I. or carbon content. The graph below illustrates actual test data on a pulverizer with varied fineness. Numerous tests were conducted at various feed rates. As feed rate decreased, fineness improved. Note that better than ±10% fuel balance is not achieved until better than 70% passing 200

Higher fineness levels always promote more even distribution of fuel between a pulverizer’s separate burner lines. Better distribution promotes better combustion, inherently lower NOx emissions and lower flyash L.O.I. or carbon content. The graph below illustrates actual test data on a pulverizer with varied fineness. Numerous tests were conducted at various feed rates. As feed rate decreased, fineness improved. Note that better than ±10% fuel balance is not achieved until better than 70% passing 200

Mesh is achieved.

When >10% fuel imbalance is observed, burner lines with higher fuel flows typically have less desirable fineness. Burner lines that have less fuel typically have better coal fineness. When this occurs the adverse effects on combustion are compounded. Burners having more fuel make effective mixing of combustion air with the coal-air mixture difficult. The adverse effects are compounded because burners having more coal will likely be of lower fineness making it even more difficult to achieve complete combustion in the burner belt zone.

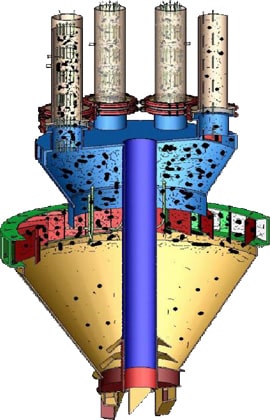

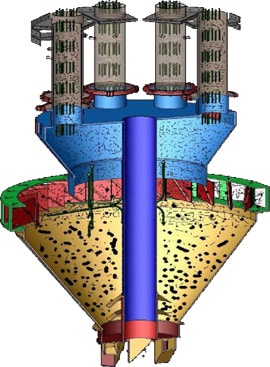

Poor Coal Fineness often yields poor distribution as large coal particles & air mix to form a (2) phase mixture which will not homogenize.

Poor Coal Fineness often yields poor distribution as large coal particles & air mix to form a (2) phase mixture which will not homogenize.

Good Fineness Creates a homogenous & balanced mixture which behaves more like a gas than a (2) phase mixture of air & fuel

Good Fineness Creates a homogenous & balanced mixture which behaves more like a gas than a (2) phase mixture of air & fuel