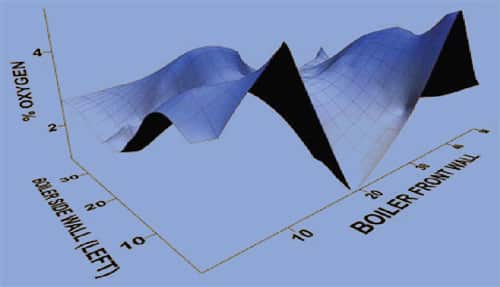

The greatest benefit to performing HVT testing is that it allows the user to identify combustion parameters as close to the combustion zone as possible. Results of the test are indicative of furnace cavity characteristics that are not “biased” by possible “air leakage.” Data collected can assist in identifying extreme fuel imbalances, secondary air imbalances, closed secondary air registers, burner line fuel pluggage and instances of excessive air infiltration. For example, the figure above illustrates the Oxygen profile on a 500 MW wall fired unit. The dip or cavity in the Oxygen level correlates with an air register which was frozen in the closed position.