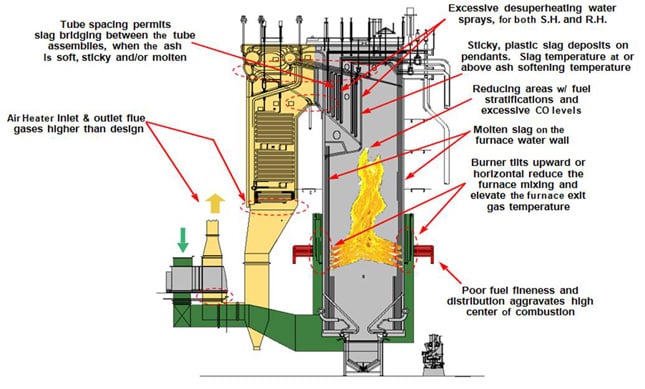

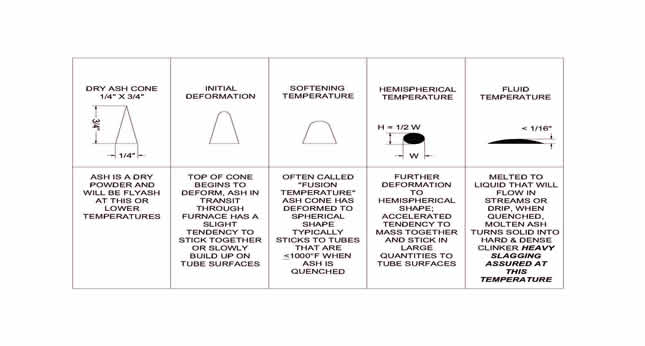

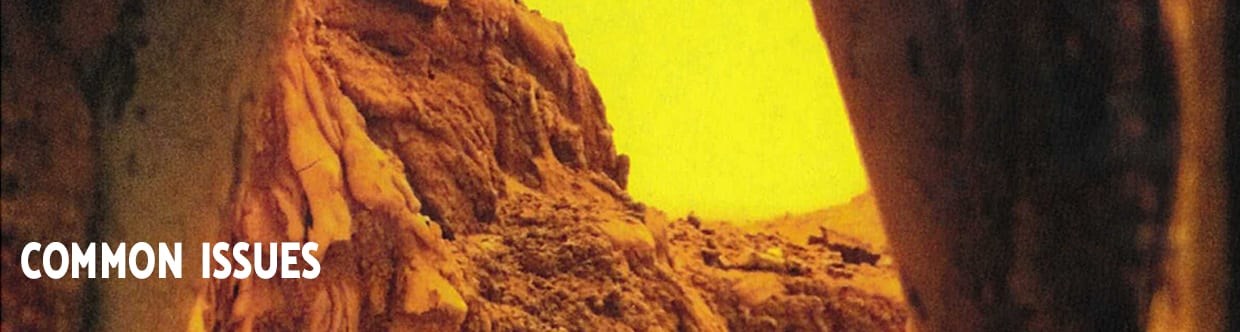

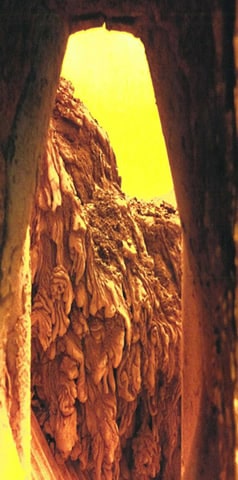

The root cause of furnace slagging is actual very simple, slagging will occur if furnace exit gas temperatures (F.E.G.T.) exceeds the fusion temperature of ash from the coal being fired. To ensure operation without slagging, we typically recommend that F.E.G.T. be 100°F to 150°F below the ash softening temperature. Higher fineness, proper primary (pulverizer) airflow and good fuel balance reduce FEGT by allowing combustion to complete lower in the furnace. When combustion is completed lower in the furnace, the waterwalls absorb a higher amount of total heat release by the fuel and FEGT is reduced.

The root cause of furnace slagging is actual very simple, slagging will occur if furnace exit gas temperatures (F.E.G.T.) exceeds the fusion temperature of ash from the coal being fired. To ensure operation without slagging, we typically recommend that F.E.G.T. be 100°F to 150°F below the ash softening temperature. Higher fineness, proper primary (pulverizer) airflow and good fuel balance reduce FEGT by allowing combustion to complete lower in the furnace. When combustion is completed lower in the furnace, the waterwalls absorb a higher amount of total heat release by the fuel and FEGT is reduced.

Reducing ash fusion temperatures are always lower than those in an Oxidizing atmosphere; a reducing atmosphere is defined as any point within the furnace cavity in which the available excess oxygen content is < 0.5%. Poor fuel balance resulting from poor fineness can result in areas of reducing atmosphere in the furnace, this will result in localized areas where ash melts into a slag, due to lower melting points caused by a reducing atmosphere.

Poor fineness is also frequently responsible for higher than desired Reheat or Superheat De- Superheating Spray Flows, heat that is not absorbed by the waterwalls must be absorbed the superheater or reheater. Additional heat absorbed by the superheat or reheater will then have to be offset by de-superheating spray flow.